Specialists in providing high quality, efficient Material Handling Systems, at AMH Material Handling, we work with our customers to design, build and maintain systems that increase workflow and productivity.

Chris Jones, Technical Director at AMH Material Handling, delves into the intricacies of managing large-scale, complex project, highlighting both the triumphs and hurdles encountered along the way.

Our client reached out to us to support with the implementation of high-tech automation to sit within their new, state-of-the-art facility, as they accommodate growing customer demands. Collaborating with a proficient team specialised in customised system solutions, we dedicated months to designing, planning, and executing. Which resulted in implementing a sortation system that can now handle up to 4,500 parcels per hour both inbound and outbound.

Process and Benefits

We delivered a cutting-edge and efficient material handling system, and through our workshop sessions we identified operational improvement’s, one which allowed a seamless transition between the clients software and our supplied WCS.

Installation

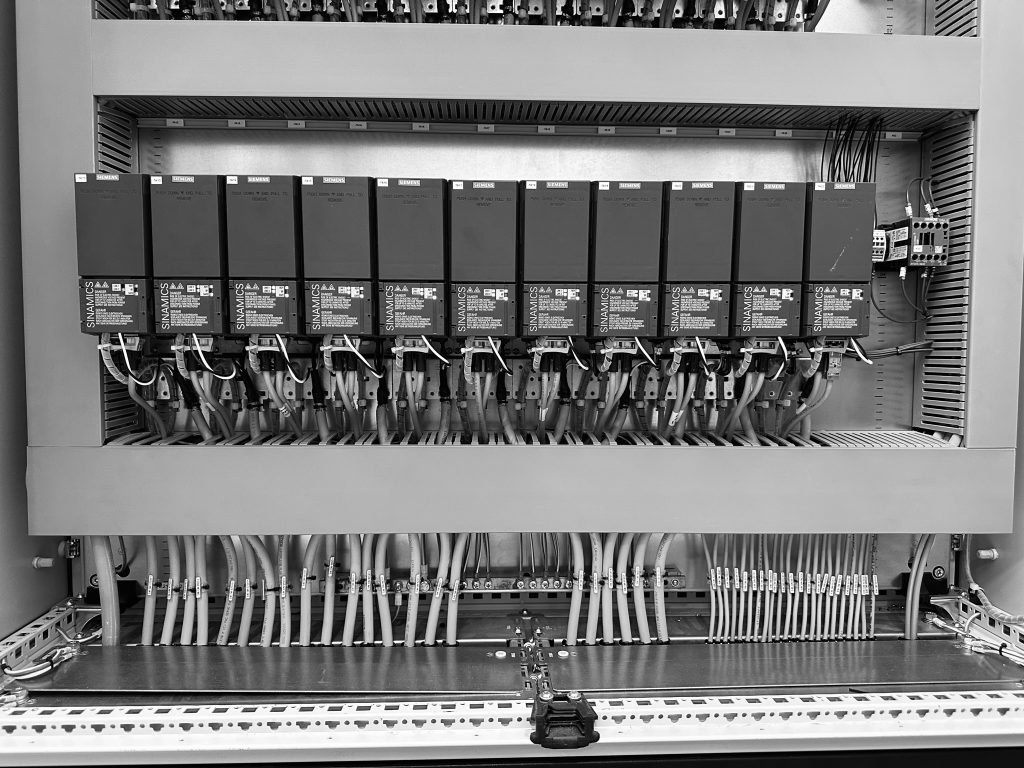

Improving parcel control around the system, we implemented Interroll powered rollers, a solution that our client had never used before; this created a huge impact on the control we had across the parcel system, and allowed for a clean and efficient installation and commissioning period when onsite.

Collaboration

I am really proud of all teams involved, with support from the AMH Design, Controls and Project Management team, as well as our partnership with SAS and SES who were on hand to support us throughout the Mechanical and Electrical installation phase. Richard Towne from IDC ltd was particularly influential throughout the delivery of this project, with the supply of IDC’s SimpliTrak™ Warehouse Control System. “Managing this project for AMH Material Handling was a remarkable journey that stretched my expertise to new heights. Our collaboration with the client was pivotal in achieving success. It was a fantastic learning experience, and I eagerly anticipate the next project to apply our collective insights once again.” – Alan Utting, Project Manager.

Challenges

Acknowledging the challenging nature of the installation process, we strategically overlapped work with electrical install and controls commissioning, meaning we could deliver this project on time and remain within budget.

Achievements

Completing this project brought immense satisfaction to our entire team. Our clients have praised the solution for enhancing efficiency and workflow, labelling the process a “true success.”

It has been a great opportunity to oversee different teams across AMH Material Handling working together to overcome challenges in developing and installing a large-scale manual handling system; as we progress, we look forward to collaborating with clients on more projects like this in the future.