AMH Material Handling has completed two projects for George clothing at the Asda Lymedale facility in Newcastle-under-Lyme. The projects have seen AMH increase storage capacity by 250,000 units and significantly speed up order throughput for George’s ecommerce operation.

In a nutshell...

The 1.2 million sq ft Lymedale facility provides store replenishment regionally and services the ecommerce business nationally. Hosted over three mezzanine floors, the facility handles the replenishment of stock for 174 stores as well as the pick, pack and despatch for UK and International online orders.

- 1.2 million sq ft facility

- Increased storage units capacity by: 250,000

- Increased carton live locations capacity by: 19,000

- Additional 1,000 linear metres of GOH storage

Project One:

Increasing Storage Capacity

Asda has seen tremendous growth for the George ecommerce business which has been operating from this site since 2013. The Lymedale facility was originally designed to hold one million units of stock on site but the operation soon outgrew this.

In order to increase storage capacity, AMH Material Handling was tasked with creating additional space in the warehouse. They managed to achieve this by reorganising both the retail and ecommerce operations. This involved carton live storage, goods on hanger (GOH) storage and conveyor routing.

The extra space created allowed AMH to supplement the existing storage. They supplied and installed additional carton live storage to increase capacity by 19,000 locations and 4,800 SKU locations. Additionally a further 1,000 linear metres of hanging garment storage was supplied and installed.

As a result of reorganising the retail storage area, the existing conveyor system and replenishment spurs which serviced the retail operation no longer fitted in with

the new layout.

Overcoming Layout Challenges

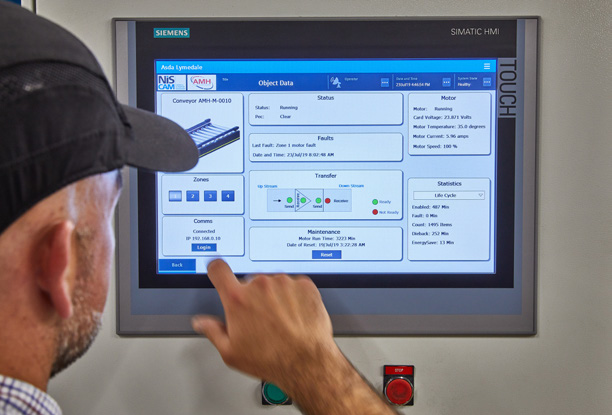

To overcome this, AMH changed the routing of all cartons and re-positioned the carton live replenishment spurs to accommodate the new warehouse layout. As the facility was still operational, the material handling specialist had to ensure that any changes caused minimal disruption to both the retail and ecommerce businesses operating from the site.

AMH was able to design and manage a solution that allowed it to install all new conveyor routing as well as test and commission the system. This had

to be completed before sign-off so the old system could be turned off and the operation switched over to the new system.

Once the conveyor system had been rerouted, AMH needed to design and install a new method of removing cardboard waste for recycling from the mezzanine levels. The waste had to be transported by conveyor to the existing baler on site.

AMH overcame this challenge by designing a bespoke solution that allows waste cardboard to travel on high level conveyors, eliminating the need to

take up valuable floor space.

The 400 metre conveyor system allows waste to travel from both the left and right sides of the warehouse. The two conveyors meet in the middle where they are joined via a drop slide which transports the waste to the baler system.

AMH designed a bespoke slide system in fibreglass which guarantees that cardboard boxes lay flat whilst travelling through the remainder of the system. This was necessary due to the low overhead clearance above the waste conveyor. In fact, the clearance was so tight that it also required AMH to make the necessary alterations to site services along the way. This included sprinkler, lighting, power distribution and communication networks.

Increasing Efficiency for Hanging Garment

As part of project one, AMH also aided Asda by increasing efficiencies with its hanging garment system for its retail operation. Items travel through the warehouse on an automated garment hanging system which uses jets to hold the garment hangers securely in place.

AMH designed and installed an improved empty jet routing system which automates the return and storage of empty jets. Previously empty jets were returned manually by operators which was not only time consuming but also delayed the retail operation as the system waited for empty jets to be returned to the goods inbound area. The new system has increased efficiencies within the goods inbound area and allows for faster processing.

Project Two:

Increasing Ecommerce Order Throughput

The second project AMH Material Handling completed at the Asda Lymedale site for George clothing was to increase order throughput and processing speeds for the ecommerce operation. Essentially, George needed to be able to pick, pack and despatch orders faster to keep up with increasing demands.

In order to facilitate this, AMH removed the old conveyor system and designed and installed a new conveyor system to deliver customer orders to eight packing benches. Each order is picked and placed into a tote. The tote is then put onto the conveyor system where it travels from level two down to level one and is delivered directly to the packing benches on a gravity decline conveyor spur. AMH also installed eight new packing benches around the spurs, allowing for more order processing.

To increase the throughput and speed of order bagging, a third automated bagging machine was installed. AMH managed the design and layout of the bagging area to accommodate the third bagging machine. They needed to ensure all orders from the bagging machine were directed to an induct station for the existing despatch sorter.

To handle this, a second induction station was installed to take bagged packages to the despatch sortation area. This required AMH to install a new conveyor route to transport completed customer orders from the packing area to the new sorter induction area.

Part of the solution required the existing conveyors to be updated to add a reverse function to the conveyor to change the direction of travel. The reverse direction function allows packages to be re-directed to the second sorter induct as throughput demands dictate.